Materials, Weaves, Strength Science, Applications, and Professional-Grade Use Cases

Introduction: What Fiberglass Cloth Is and Why It’s Widely Used

Fiberglass cloth is a woven reinforcement material made from extremely fine glass fibers that engineers, fabricators, and skilled DIY users rely on to create strong, lightweight composite structures. Professionals choose fiberglass cloth because it delivers predictable strength, excellent resin compatibility, and long-term durability across demanding environments. In real-world use, fiberglass cloth appears everywhere—from boat hulls and automotive panels to aerospace components and structural repairs—because it balances performance with cost and workability. Anyone who has cut, laminated, and wet-out fiberglass cloth understands that weave choice, fabric weight, and resin pairing directly affect strength, surface finish, and longevity, which is why experienced handling matters just as much as material selection.

What Is Fiberglass Cloth? Composition, Manufacturing, and Fiber Science

Manufacturers produce fiberglass cloth by melting raw glass materials and drawing them into continuous filaments that measure only microns in diameter. These filaments form yarns, which looms then weave into fabric patterns designed for composite reinforcement. Most fiberglass cloth uses E-glass fibers due to their balance of strength, flexibility, and affordability, while higher-performance applications rely on S-glass or specialty glass fibers for superior tensile strength and impact resistance. During manufacturing, producers apply sizing chemistry to the fibers, which improves resin bonding and protects the filaments during handling. Small changes in filament diameter, weave density, and surface treatment significantly influence how fiberglass cloth wets out with epoxy, polyester, or vinyl ester resins, making manufacturing quality a key factor in final performance.

Read for more info: https://thefashionvogue.com/bueno-clothes-logo/

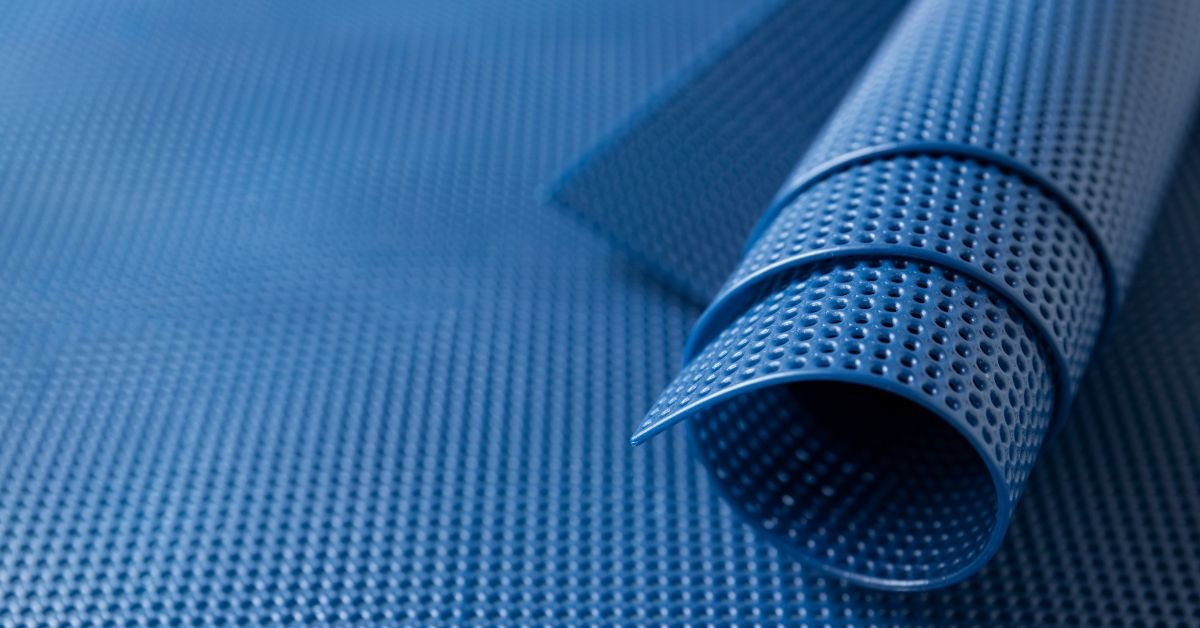

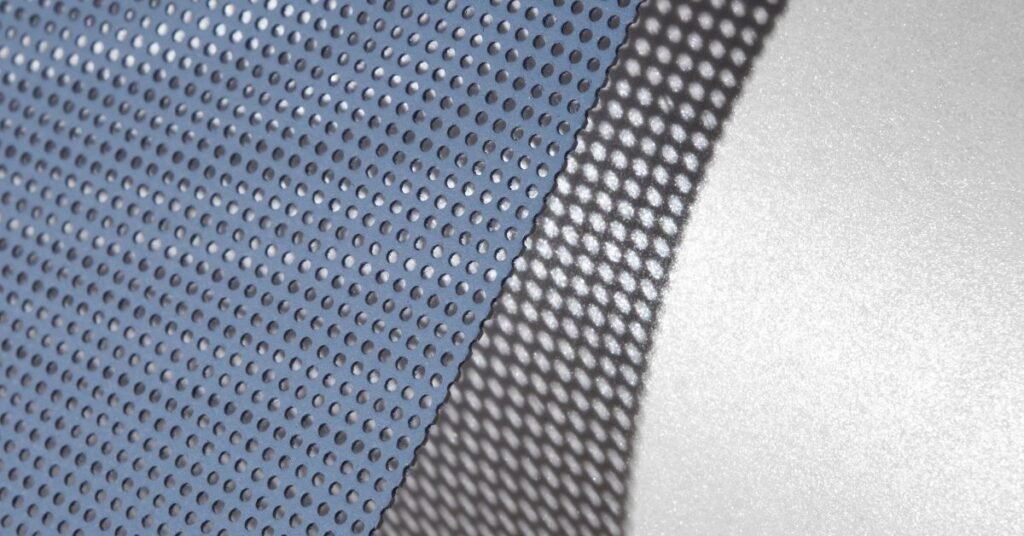

Types of Fiberglass Cloth and Weave Patterns

Fiberglass cloth behaves very differently depending on its weave pattern and fabric weight, especially during hands-on applications like mold layups or boat repairs. Plain weave fiberglass cloth offers balanced strength and excellent dimensional stability, making it easy to handle and ideal for general-purpose reinforcement. Twill weave fiberglass cloth drapes more easily over curves and complex shapes, which helps reduce air pockets during lamination, while satin weave fabrics provide the smoothest finish but require careful handling to avoid distortion. Lightweight finishing cloth works best for surface layers and cosmetic strength, whereas heavy structural cloth delivers load-bearing reinforcement in high-stress areas. Specialty fiberglass cloths, including fire-resistant, electrical-grade, and coated variants, address specific performance requirements where standard fabrics fall short.

Fiberglass Cloth vs Fiberglass Mat vs Carbon Fiber

Choosing between fiberglass cloth, fiberglass mat, and carbon fiber depends on performance goals rather than marketing claims. Fiberglass cloth delivers directional strength, clean resin wet-out, and consistent laminate thickness, making it the preferred choice for structural composites. Fiberglass mat, which uses randomly oriented fibers, builds thickness quickly but sacrifices strength efficiency and resin economy. Carbon fiber offers exceptional stiffness and weight savings but comes at a significantly higher cost and demands advanced handling skills. Installers with real-world experience often favor fiberglass cloth because it strikes the best balance between strength, affordability, and ease of repair.

Material Comparison Table

| Material | Strength-to-Weight | Resin Efficiency | Ease of Use | Cost Level |

| Fiberglass Cloth | High | Excellent | Moderate | Low |

| Fiberglass Mat | Medium | Poor | Easy | Low |

| Carbon Fiber | Very High | Excellent | Advanced | High |

Mechanical Properties and Performance Characteristics

Fiberglass cloth delivers reliable tensile and flexural strength when properly laminated, allowing structures to withstand bending, vibration, and repeated loading without cracking. The material resists impact better than many rigid reinforcements, which makes it suitable for marine and automotive environments where shock loads occur. Fiberglass cloth also tolerates wide temperature ranges and resists corrosion from moisture, fuels, and many chemicals. In applied terms, a well-designed fiberglass cloth laminate maintains structural integrity under heat cycling, prolonged water exposure, and mechanical stress, provided the fabric weight and resin system match the application.

Applications of Fiberglass Cloth Across Industries

Industries adopt fiberglass cloth because it adapts to vastly different performance demands without excessive cost. Marine builders use it to create strong, water-resistant hulls and decks, while automotive and motorsports professionals rely on it for body panels, fairings, and structural reinforcements. Construction teams apply fiberglass cloth to strengthen concrete, repair damaged surfaces, and improve durability without adding excessive weight. Aerospace and industrial manufacturers use high-grade fiberglass cloth for insulation, tooling, and secondary structural components. DIY users also depend on fiberglass cloth for home repairs, mold making, and custom fabrication projects where strength and flexibility matter.

How to Choose the Right Fiberglass Cloth for Your Project

Selecting the right fiberglass cloth starts with understanding the load the finished part must carry, the resin system you plan to use, the surface finish you want, and the environment the composite will face. Experienced fabricators evaluate these factors together rather than in isolation, since a heavy cloth paired with the wrong resin or used in a cosmetic layer often creates more problems than benefits. A professional selection framework helps avoid overbuilding, resin waste, and premature failure while ensuring the laminate performs as intended.

- The most reliable results come from matching cloth weight, weave style, resin type, and exposure conditions instead of choosing based on strength ratings alone.

Working With Fiberglass Cloth: Handling, Cutting, and Layup Techniques

Hands-on experience with fiberglass cloth quickly teaches that careful handling prevents costly mistakes. Cutting the fabric with sharp tools minimizes fraying and preserves weave integrity, while proper layup techniques ensure full resin saturation without excess pooling. Installers achieve stronger laminates by working resin through the cloth evenly, rolling out trapped air, and orienting layers to distribute loads effectively. Layer alignment and overlap control also play a critical role in preventing weak points, especially in high-stress or curved areas.

Safety, Health, and Environmental Considerations

Working with fiberglass cloth requires attention to safety because airborne fibers and resin fumes can irritate skin, eyes, and lungs. Professionals wear appropriate PPE, including gloves, respirators, and protective clothing, and maintain proper ventilation during cutting and lamination. Responsible disposal of waste materials and resin containers further supports environmental safety and regulatory compliance. Transparent safety practices not only protect workers but also reinforce trust in professional composite fabrication.

Maintenance, Durability, and Longevity of Fiberglass Cloth Composites

Fiberglass cloth composites deliver long service life when installers protect them from prolonged UV exposure and moisture intrusion. Proper sealing, surface coatings, and routine inspections prevent delamination and surface degradation over time. When damage does occur, fiberglass cloth allows for straightforward repairs that restore structural integrity without replacing entire components. This repairability makes fiberglass cloth particularly valuable in marine, automotive, and industrial settings.

Cost Analysis: Fiberglass Cloth Pricing and Value Over Time

Fiberglass cloth pricing varies based on fabric weight, weave pattern, and fiber type, but it consistently offers strong value compared to alternative reinforcements. Although heavier or specialty cloths cost more upfront, they often reduce labor time and extend service life, lowering total project costs. When evaluated over time, fiberglass cloth frequently outperforms cheaper materials that require frequent repairs or replacement.

Typical Cost Range Table

| Fiberglass Cloth Type | Approximate Price Range | Typical Use |

| Lightweight Plain Weave | Low | Finishing layers |

| Medium Structural Cloth | Medium | General reinforcement |

| Heavy or Specialty Cloth | High | High-stress applications |

Common Mistakes and Professional Tips

Professionals often see failures caused by incorrect cloth weight selection, inadequate resin wet-out, and mismatched resin systems. These mistakes usually stem from underestimating how fiberglass cloth behaves during real applications. Field-tested techniques, careful material pairing, and patience during layup consistently produce stronger, longer-lasting composites.

Frequently Asked Questions

Is fiberglass cloth stronger than fiberglass mat?

Fiberglass cloth provides higher strength per weight and better resin efficiency than fiberglass mat, especially in structural applications.

Can I use fiberglass cloth with epoxy resin?

Yes, fiberglass cloth works exceptionally well with epoxy resin and offers excellent bonding and durability.

How long does fiberglass cloth last?

When properly laminated and protected, fiberglass cloth composites can last decades with minimal maintenance.

What weight fiberglass cloth should I use?

The correct weight depends on load requirements, surface finish goals, and environmental exposure rather than a single strength rating.

Conclusion

Fiberglass cloth remains one of the most versatile and trusted reinforcement materials in modern composite construction. Its balance of strength, affordability, and workability makes it indispensable across marine, automotive, construction, and industrial applications. When professionals select the right weave, weight, and resin system—and apply proven handling techniques—fiberglass cloth delivers long-lasting performance that rivals far more expensive alternatives. Understanding the material at this depth allows builders and fabricators to create composites that perform reliably in the real world, not just on paper.